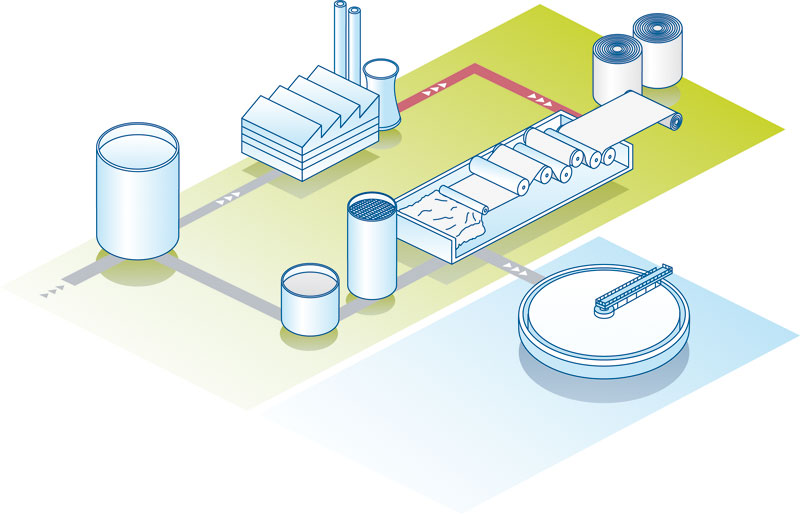

Primary & Secondary Wastewater Treatment

Because 90% of the water used in a paper mill is returned to its source, meticulous water treatment before discharge is essential. Assure pulp and paper effluent complies with regulations by monitoring and optimizing primary and secondary wastewater treatment. Save energy and chemicals with real-time adjustments based on accurate data. Hach instrumentation and solutions enable:

- Optimization of primary/secondary clarification

- Optimization of flocculation and sludge dehydration process

- Control of activated sludge retention time for foam and filamenteous protection

- Dosage control and optimization of nitrogen and phosphorus

- Monitoring of the biomass “health” with ATP measurement

- Real-time monitoring of effluent regulated parameters

- Wastewater plant data management for analysis and automatic reporting

Parameters Relevant to Water Supply Conditioning

Absorbance UV

Absorbance UV

Ammonia

Ammonia

ATP

ATP

Biochemical Oxygen Demand (BOD)

Biochemical Oxygen Demand (BOD) Flow

Flow

Nitrate

Nitrate

ORP

ORP

Oxygen

Oxygen

pH value

pH value

Phosphorus

Phosphorus Sludge Level

Sludge Level

Temperature

Temperature

Total Organic Carbon (TOC)

Total Organic Carbon (TOC)

Turbidity and Total Suspended Solids (TSS)

Turbidity and Total Suspended Solids (TSS)

How to Measure:

- BioTector B7000i TOC Analyzer

- BioTector B3500e TOC Analyzer

- AMTAX sc Ammonium Analyzer

- PHOSPHAX sc Phosphate Analyzer

- Differential pH Digital Sensors

- UVAS plus sc UV Probe Sensor

- LDO sc Luminescent Dissolved Oxygen Sensor

- TSSsc Turbidity and Suspended Solids Sensors

- Solitax sc Turbidity and Suspended Solids Probes

- Filtrax Sample filtration system

- HQ440D Laboratory pH Meter Package

- Grab Samplers

- Portable Samplers

- RTC-SD Sludge Dewatering Software

- RTC-SRT Aeration Process Software

- RTC-DAF Software

- RTC-DOS Nutrient Dosing Software

- WIMS Water Information Management Solution

- NITRATAX Nitrate Sensors

- LuminUltra ATP Test Kits

- Sonatax Sludge Level Sensor

Process solutions include online sensors that provide round-the-clock support for critical operational and process decision making.

Laboratory solutions include simple, reliable and accurate tests that support quality and compliance decision making.