Increase Water Filtration Membrane Performance

Improve Efficiency and Control Membrane Filtration Cost

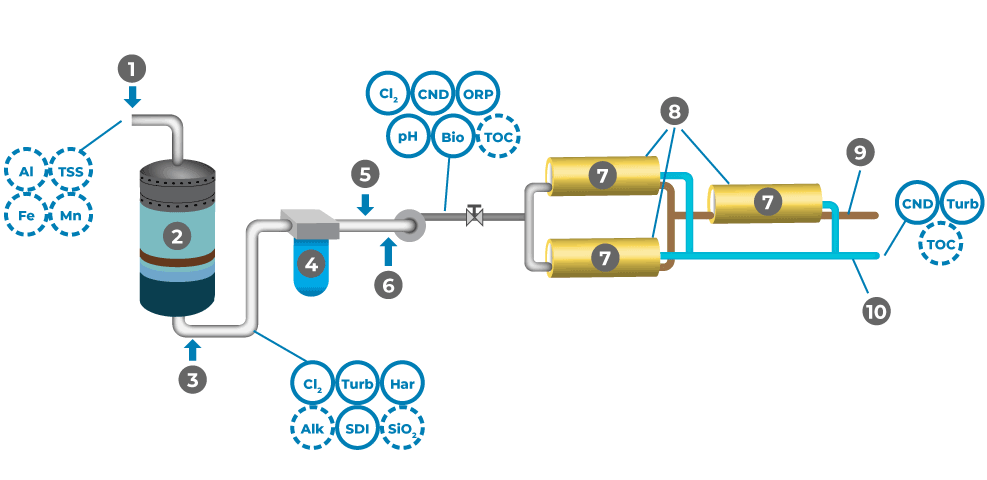

Reverse osmosis (RO) membranes have arguably a greater impact on operations than any other water treatment process. They are extremely effective in removing inorganic contaminants, but they are also highly susceptible to fouling, oxidation, and scaling. A lack of precise, real-time monitoring to control RO membranes can drive significant costs in the form of biofouling, excessive chemical use, frequent cleaning and maintenance, plant downtime, and early membrane replacement.

RO Fouling Expenses

According to a recent study in the scientific journal, Desalination, the cost of RO fouling at one desalination plant in the Netherlands represents approximately 24% of total plant operating expenses. The bulk of that expense is incurred by early replacement of membranes. 1

How Do RO Membranes Work?

Reverse osmosis applies pressure to a semipermeable membrane that allows water molecules to pass through as dissolved inorganic compounds are flushed to the drain. Cross-flow separates the water into two pathways.

Dechlorination and Membrane Monitoring

There are many parameters that are important when monitoring RO membrane performance, one of the most critical is chlorine. Chlorination and dechlorination are key steps in nearly all industrial and municipal treatment processes when RO membranes are used. As it is difficult to detect exact levels of chlorine, plant operators will often opt to completely remove all traces of it. While the end result is zero residual chlorine (meeting water quality goals) over-dechlorination can cause a host of unnecessary consequences and expenses along the way.

1

There is the cost associated with the superfluous chemicals used to completely remove chlorine.

2

The absence of chlorine can lead to biofouling, which then requires additional cleaning and maintenance or the use of costly biocides.

3

The efficiency of the membranes is negatively impacted, forcing replacement months sooner than would normally be required.

Example 1:

Extend Membrane Life

Many membranes are rated to 1,000 parts per million (ppm) -hours of free chlorine exposure before salts passage doubles. If you expose your first-stage RO to a continuous average of 38 parts per billion (ppb), you will reach 1,000 ppm hours in 36 months.

If you increase your average exposure by just 10 ppb to 48 ppb, you will reach the same 1,000 ppm-hours in 28.5 months. That means potentially replacing your first-stage RO membranes seven and a half months sooner from an average increase of 10 ppb free chlorine exposure.

Example 2:

Reduce Cleaning Costs

Your facility might spend as much as four times the amount cleaning membranes for the same unit of water if not properly maintained, versus a properly maintained system at a quarter of the cost.

Reduce Operating Costs

When membranes foul the costs are substantially higher. Operations could increase by 50% to as much as 100% for a typical plant. 2

Other Hach Products for Membrane Monitoring

TU5300sc/TU5400sc Online Laser Turbidimeters

Turbidity

Monitor turbidity before and after nanofiltration (NF) and RO to capture membrane performance and breakthrough potential. Use this information to adjust your process upstream to reduce maintenance and improve membrane longevity.

Shop Now

Surface Scatter 7 sc High Range Turbidimeter

Turbidity

Turbidity readings enable you to monitor process control in feedwater with higher turbidity levels and fouling potential. With real-time visibility to turbidity spikes, you can act quickly to prevent early membrane fouling.

Shop Now

EZ Series Hardness Analysers

Hardness and Membrane Fouling

Hardness can increase scaling potential, impacting membrane performance and longevity. Monitor the performance of your ion exchange process controlling hardness levels.

Shop Now

pH & ORP Sensors

pH Control for Membrane Protection

Many NF and RO membranes are sensitive to pH levels. Monitor pH for early warning signs of potential scaling, membrane degradation and efficiency loss.

Shop Now

1Jafari, M. et al. “Cost of fouling in full-scale reverse osmosis and nanofiltration installations in the Netherlands.” Desalination, March 2021. https://doi.org/10.1016/j.desal.2020.114865

2SAMCO. “How Much Does It Cost to Properly Maintain Membrane Filtration Systems vs. Treat Fouled Membranes?” February 2019. https://www.samcotech.com/cost-to-properly-maintain-membrane-filtration-systems

Recurring Orders

Recurring Orders