Featured Products to Monitor Hydrogen Sulfide

H₂S Sensors

Hydrogen sulfide sensors provide accurate, reliable H₂S measurement in water or air to help you tackle reduce unnecessary spending on chemical dosing while delivering reliable, real-time H₂S monitoring.

Shop Now

H₂S Lab & Portable Instruments

Get fast and reliable measurement of H₂S in water with Hach's line of lab meters. These versatile instruments also have you covered on a wide range of water quality parameters including hydrogen sulfide.

Shop Now

Hydrogen Sulfide Test Kits

Hydrogen sulfide test kits are the most economical method for determining H₂S levels in water samples. H₂S test kits contain all required reagents and apparatus to start testing in the lab or in the field.

Shop Now

SC4500 Controllers

When coupled with the simplicity of the SC4500 controller, Hach’s H₂S sensors make it easier than ever to make data-driven decisions and optimize chemical usage—saving your facility time, effort, and operational costs.

Shop Now

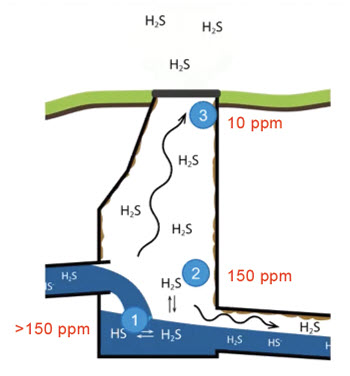

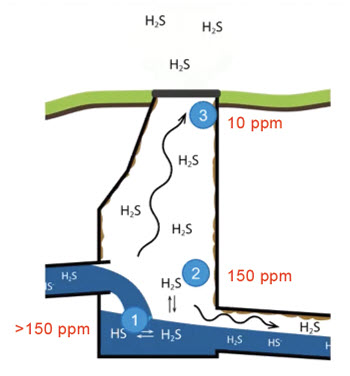

Even small quantities of H₂S can lead to big problems. Its ‘rotting egg’ odor is noticeable at 0.5 parts per million (ppm) and corrosion also starts at 0.5 ppm. But the concentration measured near the top of a manhole can be vastly different than that measured in the wastewater itself. Knowing the worst-case scenario by monitoring H₂S in the wastewater can have tremendous influences on the outcomes of hydrogen sulfide’s three greatest challenges:

Worker Safety

While odor complaints from the public are a nuisance, worker fatalities in wastewater environments are far worse—and unfortunately, they still occur.

Monitoring H₂S earlier in the collection system or at the WWTP allows utilities to:

- Detect dangerous levels sooner

- Take proactive, precautionary steps

- Protect workers from life-threatening exposure

Liquid-phase readings provide the most realistic risk assessment for safety planning.

Odor Control

As communities expand, WWTPs are now closer to homes and businesses. This increases the likelihood of odor issues reaching the public.

To stay ahead of complaints and PR fallout, utilities should:

- Measure H₂S at its worst—in the liquid stream of collection feeder lines and at plant inlets

- Neutralize odors before they spread to nearby neighborhoods

Accurate liquid-phase detection is key to effective odor control.

Corrosion Control

H₂S doesn’t just smell bad—it destroys infrastructure. In wastewater pipes, biofilms convert H₂S to sulfuric acid. This along with with undetected crown-rot corrosion can cause numerous problems:

- Eats away at concrete surfaces

- Turns material into flaky gypsum

- Corrodes reinforcing steel

- Weakens overall pipe structure

- Structural collapse

- Damage to surrounding infrastructure

- Costly and complex repairs

Continuous H₂S monitoring helps detect early signs of deterioration, guiding inspection schedules and protecting assets.

Where hydrogen-sulfide measurement takes place can have a major influence on the accuracy of the reading and the ability to manage the problem cost effectively.

The highest concentrations and most consistently indicative readings are found in the wastewater itself (1). The air in the headspace just above the water (2) will typically give the next most concentrated reading, which can be 15x greater than the concentrations recorded at the top of a manhole (3).

The Advantages Of Liquid Measurement

While the sensitivity of the human nose makes it an early detection system for the presence of hydrogen sulfide gas, it is not a foolproof solution. In fact, high concentrations can quickly neutralize the nose’s ability to smell this invisible gas and quickly incapacitate the individual exposed to it.

In wastewater environments, it's a mistake to assume that gas-phase and liquid-phase H₂S readings are interchangeable for several reasons:

- Liquid-phase detection identifies H₂S at its highest concentrations, which may not be exposed to gas-phase sensors.

- These more accurate readings help operators:

- Detect issues earlier

- Choose the most cost-effective strategies for neutralization

- Avoid underestimating potential hazards

Using sensors capable of measuring both liquid and gas phases provides the best coverage for:

- Continuous monitoring or spot-checking

- Multiple locations within a collection system or treatment plant

- Addressing concerns related to safety, odor control, and corrosion protection

Understand Where Liquid Measurement Saves Money

Being able to map locations where hydrogen sulfide is generated and collects is the first step to understanding the most efficient treatment reagent and dosing at the right location. While wastewater collection and treatment operators often have a sense of their traditional hydrogen-sulfide problem areas, the actual concentrations there can vary widely over time.

By continuously tracking actual H₂S concentrations in liquid, operators gain:

- The ability to adjust treatment in real time as levels fluctuate

- Better dosing decisions, reducing chemical waste and costs

- A clearer view of where and when to invest in treatment

Liquid-phase measurement is the most accurate indicator of H₂S loading, enabling cost savings even under variable conditions.

Recurring Orders

Recurring Orders